china slurry pump rubber spare parts manufacturers

Latest articles

The length of the piping. The longer the pipe, the more slurry-induced friction the pump needs to overcome.

china slurry pump rubber spare parts manufacturers...

china slurry pump rubber spare parts manufacturers 【china slurry pump rubber spare parts manufacturers】

Read More>Slurry pumps are typically larger than standard pumps, with more horsepower and stronger bearings and shafts. The most common type of slurry pump is the centrifugal pump. These pumps use a rotating impeller to move the slurry, similar to the way aqueous liquids move through a standard centrifugal pump.

china slurry pump rubber spare parts manufacturers...

china slurry pump rubber spare parts manufacturers 【china slurry pump rubber spare parts manufacturers】

Read MoreConveying medium

china slurry pump rubber spare parts manufacturers...

china slurry pump rubber spare parts manufacturers 【china slurry pump rubber spare parts manufacturers】

Read MorePumping mud is not as easy as pumping water. Depending on the type of slurry, there are many variables in choosing the right pump for the slurry. There is no formula or set-in-stone answer as to what the best slurry pump design is. You must combine knowledge and application details to select the ideal , slurry pump, . Lets talk about how slurry pumps differ from standard pumps and how to narrow your choices.

china slurry pump rubber spare parts manufacturers...

china slurry pump rubber spare parts manufacturers 【china slurry pump rubber spare parts manufacturers】

Read MoreFind a professional slurry pump supplier

china slurry pump rubber spare parts manufacturers...

china slurry pump rubber spare parts manufacturers 【china slurry pump rubber spare parts manufacturers】

Read MoreExpertise and experience

china slurry pump rubber spare parts manufacturers...

china slurry pump rubber spare parts manufacturers 【china slurry pump rubber spare parts manufacturers】

Read MoreA dredge pump contains a pump casing and an impeller. The impeller is mounted in the pump casing and connected to the drive motor via a gearbox and shaft. The front part of the pump casing is sealed with a suction cover and connected directly to the suction pipe of the dredger. The discharge port of the dredge pump is located near the top of the dredge pump and is connected to a separate discharge line.

china slurry pump rubber spare parts manufacturers...

china slurry pump rubber spare parts manufacturers 【china slurry pump rubber spare parts manufacturers】

Read MoreOn the other hand, if the slurry is not only abrasive but also has a low pH, then a duplex stainless steel construction is preferable. This material is best suited for slurry pumps to withstand harsh materials (such as acids) while still having a high Brinell hardness.

china slurry pump rubber spare parts manufacturers...

china slurry pump rubber spare parts manufacturers 【china slurry pump rubber spare parts manufacturers】

Read MoreAier Machinery's team of consultants are on hand to provide you with a solution to your needs. Whether you are planning to purchase a slurry pump or need spare parts for an existing pump, we will help you determine your needs and provide advice on fine-tuning your equipment to your specific application.

china slurry pump rubber spare parts manufacturers...

china slurry pump rubber spare parts manufacturers 【china slurry pump rubber spare parts manufacturers】

Read MoreThe company uses advanced computer assistant engineering software to design products and technology, which makes our method and level of design reach international advanced level. The company has the first-class pump performance testing station in the world, and its test capacity can reach 13000m³/h. Annual output of our products is 10000 sets or tons on high chrome alloy castings. Main products are Type WA, WG, WL, WN, WY, WZ, etc. Size: 25-1200mm,

china slurry pump rubber spare parts manufacturers...

china slurry pump rubber spare parts manufacturers 【china slurry pump rubber spare parts manufacturers】

Read More

Popular articles

- Positive displacement slurry pumps with limited capacity to deliver high head are used to pump slurry through pipes with very high solids concentrations.

- Aier Machinery has strong technical force and is specially engaged in the research of abrasion resistant materials of slurry pumps, sewage pumps and water pumps and the development of new products. The materials include high chrome white iron, duplex stainless steel, stainless steel, ductile iron, rubber, etc.

- Slurry pump considerations

- Light-duty Slurry Pump

- Packing the box seal

- Because of these requirements, slurry pumps are usually larger than their clear liquid counterparts. In addition, it usually sacrifices efficiency, i.e. maximum efficiency and efficiency throughout its operating range, in exchange for the ability to achieve good operation in these challenging services.

Latest articles

-

Slurry Pump

-

In harsh conditions with sand, sludge, rocks and mud, ordinary slurry pumps tend to clog, wear and fail frequently. But WA heavy duty slurry pumps are highly resistant to wear and corrosion, which means that the service life of our slurry pumps is better than other manufacturers' pumps.

-

Some models can generate discharge pressures up to 260 ft. (80 m).

-

As described below, there are several , types of pumps, that are suitable for pumping slurries. However, before considering which technology to use, we must address several key issues.

-

-When pumping abrasive slurries, it is essential to use wear-resistant components with a high chromium content. But more is not always better - above 25%, the impeller becomes brittle.

-

Step 2

Links

The Anatomy of a Control Box

- 3

The rubber adhesive used in Polyethylene Rubber Tape offers several advantages that contribute to its performance and effectiveness.

- The science behind fire retardant duct tape lies in its unique composition. Unlike conventional tapes, which can quickly ignite or melt when exposed to high temperatures, this variety is impregnated with chemicals that inhibit flame growth. These chemicals work by interrupting the combustion cycle, effectively starving the fire of oxygen. Moreover, the adhesive used in these tapes is designed to maintain its integrity even under intense heat, preventing it from degrading or releasing toxic fumes.

Durability and longevity: Silicone rubber tapes offer excellent longevity and toughness, making them a reliable choice for long-term repairs. Rubber repair tapes, on the other hand, offer durability and flexibility, making them ideal for a variety of repair tasks.

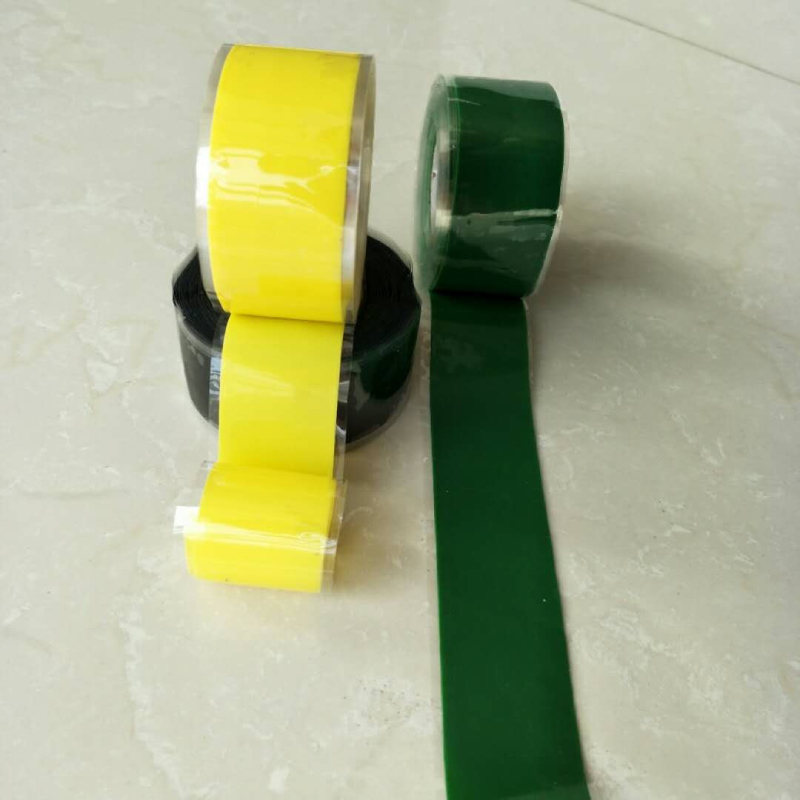

It can be customized with different colors, patterns, or even company logos, adding a touch of style to the otherwise industrial-looking engine compartment It can be customized with different colors, patterns, or even company logos, adding a touch of style to the otherwise industrial-looking engine compartment

It can be customized with different colors, patterns, or even company logos, adding a touch of style to the otherwise industrial-looking engine compartment It can be customized with different colors, patterns, or even company logos, adding a touch of style to the otherwise industrial-looking engine compartment . It comes in a variety of colors and widths, allowing you to choose the option that best suits your needs. Some types of tape are also designed to be more flexible than others, making them ideal for use in tight spaces or on irregular surfaces.

. It comes in a variety of colors and widths, allowing you to choose the option that best suits your needs. Some types of tape are also designed to be more flexible than others, making them ideal for use in tight spaces or on irregular surfaces.